Fusion Pressure Calculator

time2023/01/06

- To properly fuse pipe the fusion pressure must be adjusted so the pipe manufacturers recommended interfacial pressure is achieved.

Learn To Calculate Fusion Pressure

EXAMPLE

Using a 28 Machine from Chart A (at right) we will determine our gauge pressure.

Pipe Size = 8" IPS

OD of Pipe = 8.625

DR of Pipe = 11

IFP = 75 PSI

Measured Drag = 30 PSI

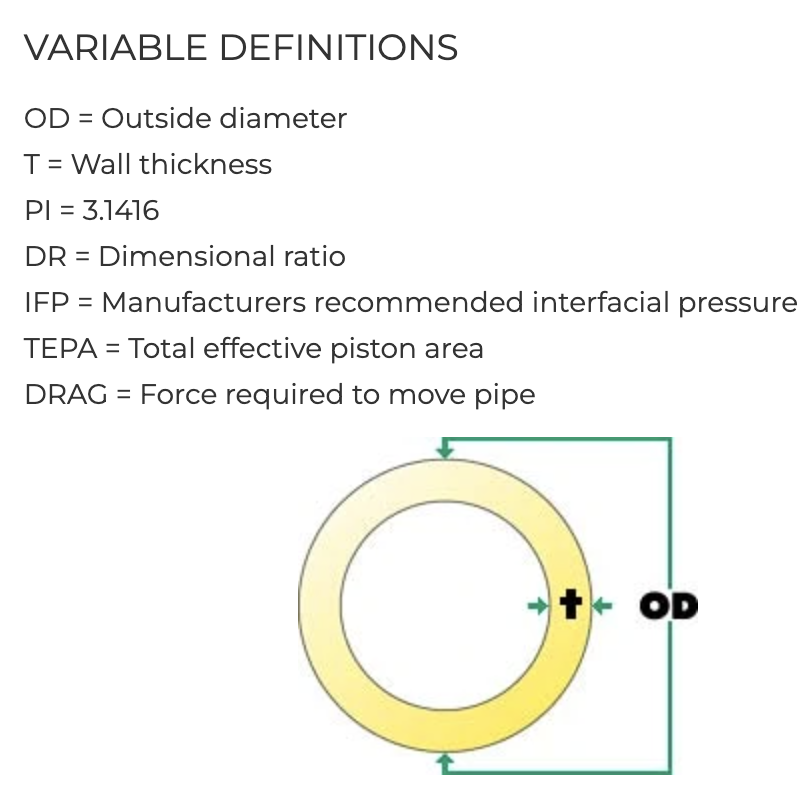

VARIABLE DEFINITIONS

OD = Outside diameter

T = Wall thickness

PI = 3.1416

DR = Dimensional ratio

IFP = Manufacturers recommended interfacial pressure

TEPA = Total effective piston area

DRAG = Force required to move pipe

Total Effective Piston Area

| Model | High Force Standard | Medium Force High Velocity | Low Force Extra High Velocity |

|---|---|---|---|

| 28 | 4.71 | NA | 1.67 |

| 412 | 11.78 | 6.01 | 3.14 |

| 618 | 11.78 | 6.01 | 3.14 |

| 500 | NA | 6.01 | NA |

| 824 | 29.44 | 15.32 | 9.45 |

| 1236 | 29.44 | 15.32 | 9.45 |

| 900 | NA | 15.32 | NA |

| 1648 | 31.42 | 14.14 | NA |

| 2065 | 31.42 | NA | NA |

STEP 1. - CALCULATING WALL THICKNESS:

To determine wall thickness we will be using the Example (above).

T = OD/DR = Wall thickness

Now the Example and the formula above we will calculate the wall thickness.

T = 8.625/11 = .784

STEP 2. - FINDING TOTAL EFFECTIVE PISTON AREA

Use Chart A (above) to find the TEPA of your machine.

TEPA = 4.710 (we are using the 28 as an example)

STEP 3. - CALCULATING GAUGE PRESSURE

Using the information we have gathered from above.

{(OD - T) x T x PI x IFP}/TEPA + DRAG = Gauge Pressure

STEP 4. - COMPLETED FORMULA

Now using all the information and the formula above we will find the gauge pressure.

{(8.625 - .784) x .784 x 3.1416 x 75}/4.710 + 30 PSI = 338 PSI

If you are working on a butt fusion project or have questions/issues relating to this process, contact our fusion specialists.