Benefits of gearing the milling cutter of the butt welder.

sourceWelping

publisherElla

time2024/01/12

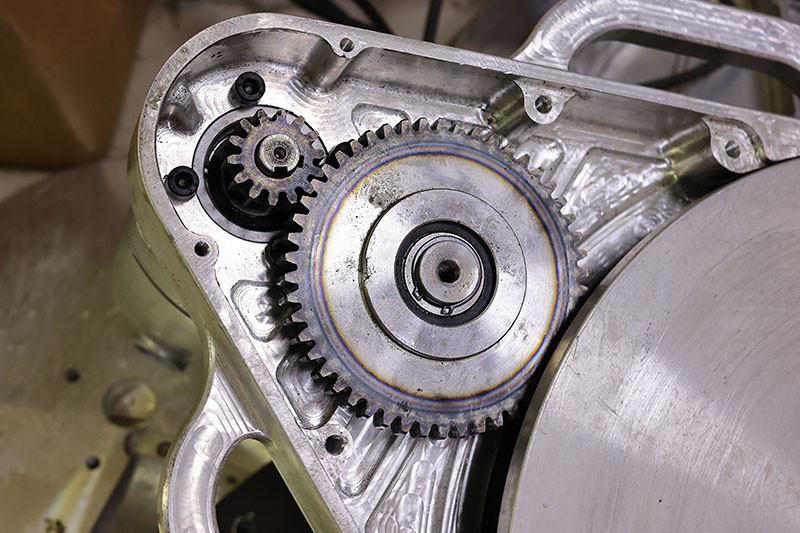

- In the equipment of butt fusion welding machines, the milling cutter is a crucial component. The milling cutter in the butt fusion welding machine is designed with a gear transmission method, which, compared to conventional designs, offers several advantages, particularly in terms of safety and durability.

In the equipment of butt fusion welding machines, the milling cutter is a crucial component. The milling cutter in the butt fusion welding machine is designed with a gear transmission method, which, compared to conventional designs, offers several advantages, particularly in terms of safety and durability.

Enhanced Safety: The gear transmission design demonstrates more stable and controllable characteristics during power transmission. This design effectively reduces sudden power fluctuations, lowering the risk of unexpected incidents during operation. For high-temperature and high-pressure equipment like hot melt welding machines, safety is paramount. The reliability of gear transmission contributes to preventing accidents and ensuring the safety of operators.

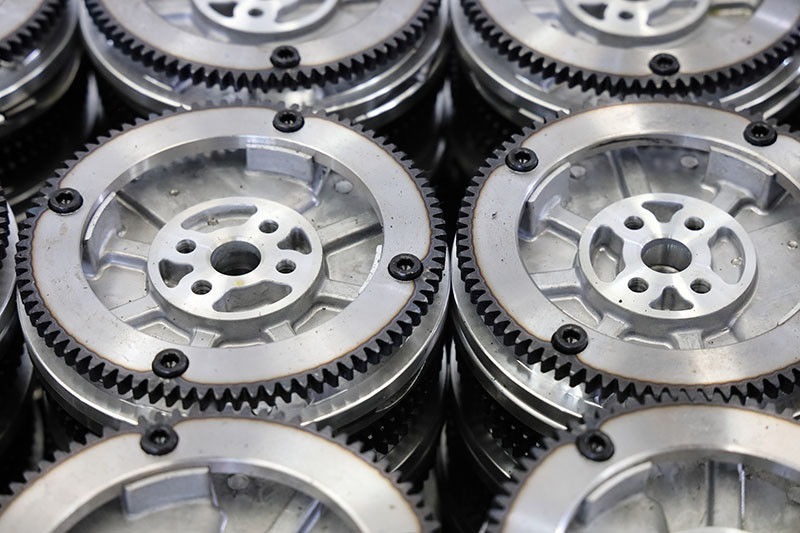

Increased Durability: Gear transmission systems typically exhibit greater durability compared to linkage designs. The gear-driven transmission minimizes wear between components, thereby extending the equipment's lifespan. This is particularly crucial for welding machines subjected to frequent and high-intensity workloads, as it enhances overall durability.

Improved Transmission Efficiency: Gear transmission designs usually provide higher transmission efficiency, reducing energy losses. This means that the butt fusion welding machine can more effectively utilize power during operation, enhancing overall work efficiency. In a production environment, increased efficiency not only saves energy costs but also boosts output.

Overall,

a butt fusion welding machine designed with gear transmission excels in terms of safety, durability, transmission efficiency, and maintenance cost reduction. It stands out as a more reliable and cost-effective choice.