What problems can the upgraded butt welding machine solve in construction?

sourceWelping

publisherElla

time2024/05/22

- Are you still troubled by these problems.All these problems can be solved by Welping butt welding machine!

Unstable power supply problem leads to the butt welding can not work properly, poor welding effect.

Poor welding quality, cracks, slag entrapment, etc.

Equipment failure, unstable welding current, hydraulic system oil leakage, contactor failure, etc.

Common faults of butt welding machines

Are you still troubled by these problems.

Unstable power supply problem leads to the butt welding can not work properly, poor welding effect.

Poor welding quality, cracks, slag entrapment, etc.

Equipment failure, unstable welding current, hydraulic system oil leakage, contactor failure, etc.

Poor construction site environment, such as high temperature, low temperature, high humidity, dust, etc. affect the welding effect and equipment operation.

All these problems can be solved by Welping butt welding machine!

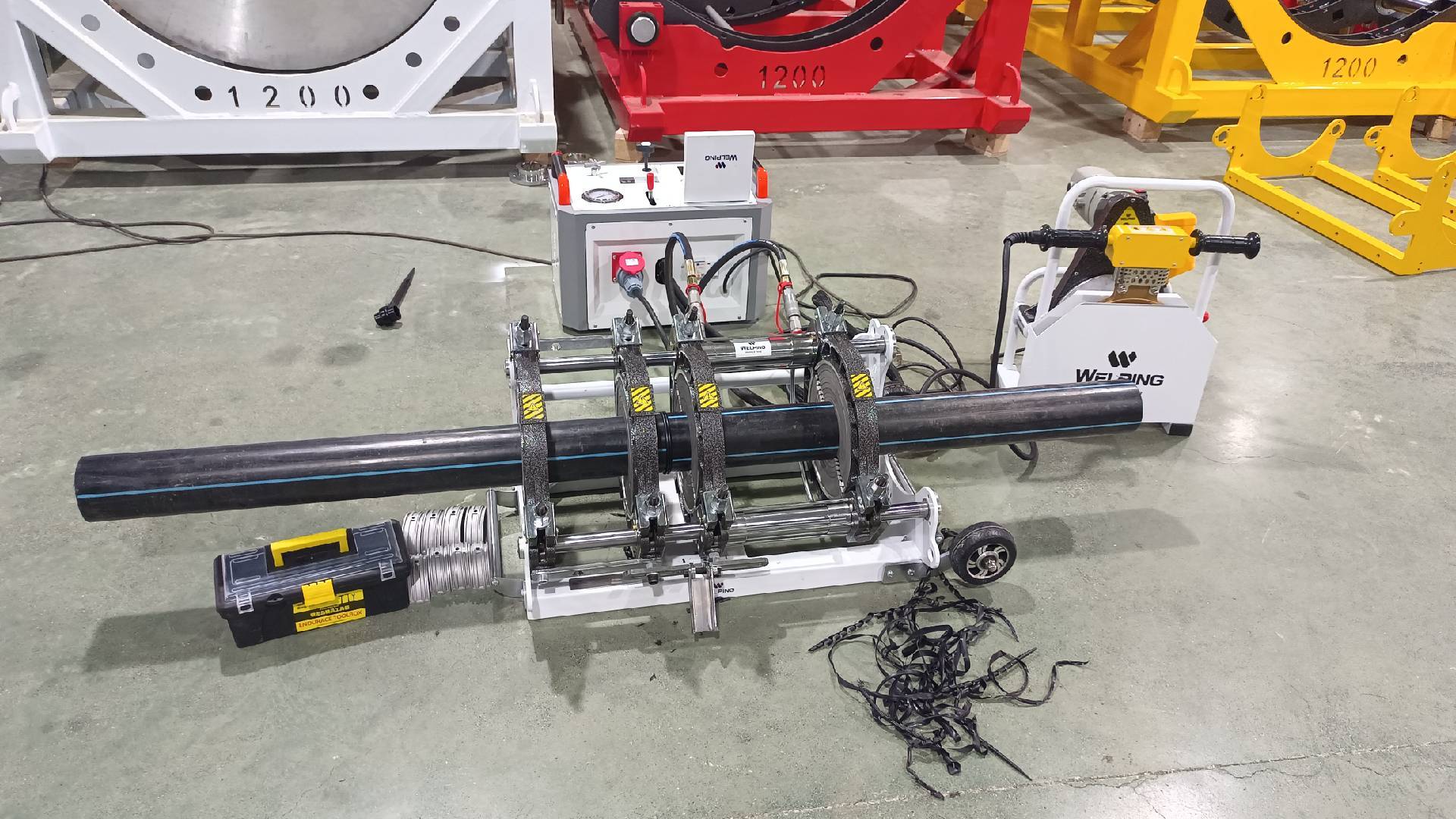

Upgraded butt welding machine

We are very pleased to recommend the newly upgraded Apro series butt welding machines to you. This machine is a comprehensive upgrade we made after in-depth research and customer feedback, aiming to provide you with a more efficient and reliable production equipment.

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

First of all, the Apro series butt welding machine uses Siemens contactors, replacing the previously used Chint contactors. This upgrade significantly improves the reliability and durability of the device. Siemens contactors are known for their excellent performance and low failure rate, ensuring that your production line can run stably and efficiently. We believe that this improvement can not only improve production efficiency, but also ensure the stability of product quality, giving you more trust in our butt welding machines.

Safe and secure

Shell flame retardant material, self-extinguishing in case of fire

Copper coil core

When the coil is energized, the static iron core generates electromagnetic attraction, which pulls the iron core together. The pull-in electric pressure is between 58% and 110%.

Optional

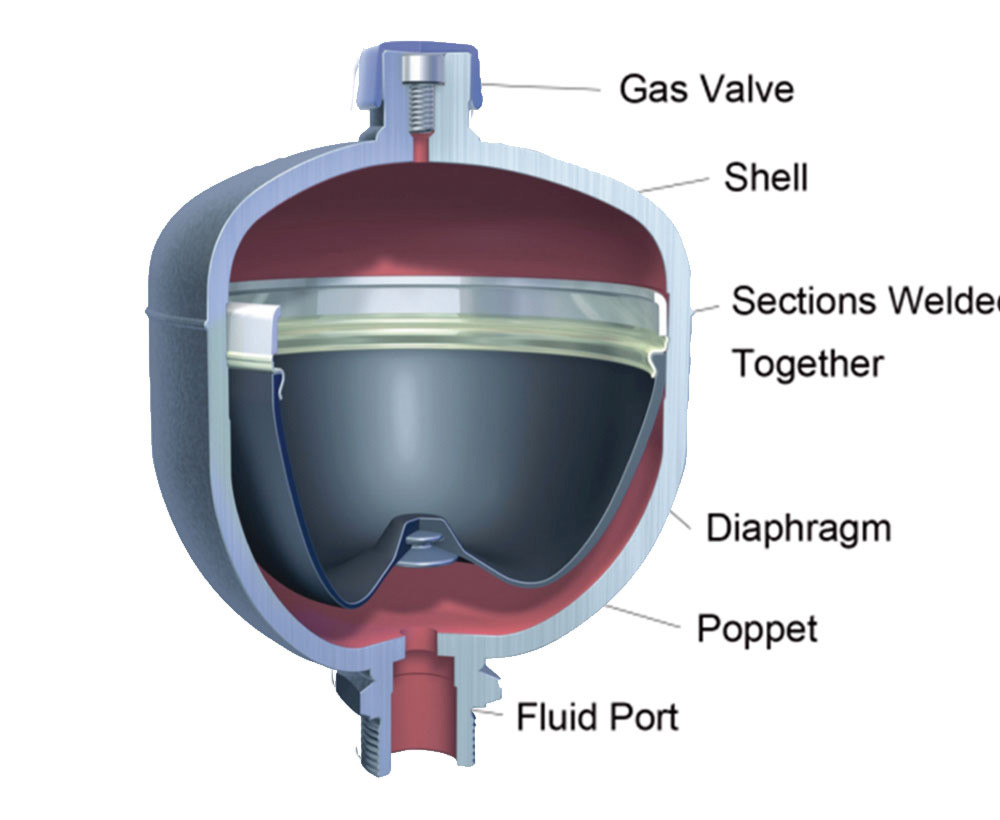

In addition, our hydraulic units are now available as an option with accumulators. The addition of the accumulator provides the hydraulic station with a more stable pressure output, significantly reduces energy consumption and extends the service life of the equipment. More importantly, in the event of a power outage, the accumulator can provide emergency power to ensure the continuity and safety of the production process and protect your production line.

Appearance upgrade

In order to further enhance the appearance and practicality of the product, we designed a hollow lettering on the side of the fuselage and added a delicate logo pattern. Not only does this make the equipment more aesthetically pleasing, it also demonstrates the uniqueness and professionalism of our brand, adding a modern and tasteful touch to your production environment.

At the same time, we have added a bottom baffle design at the bottom of the fuselage, specifically to prevent mud and debris from being involved in the butt welding joint during the milling process. This improvement not only improves the cleanliness and operational stability of the equipment, but also ensures welding quality, reduces maintenance frequency and production downtime, and further improves work efficiency.

We believe that the upgraded Apro series butt welding machines will bring a new experience and significant benefits to your production. We look forward to working with you to move towards a more efficient and reliable production future.

Thank you for your continued support and trust in us!