Beyond Flaring: How to Achieve Efficient, Leak-Free Grooved Piping Connections

time2025/08/27

- Using scientifically-grounded methods and specialized equipment, flaring can be controlled within standardized tolerances. Gruvmaster’s research into metal forming mechanisms has optimized machine design and parameters, ensuring consistent groove quality, improved installation efficiency, and reduced rework.

Recently, a contractor from Southeast Asia sent us this photo (See first picture in attachment.). They were working on a 10-inch SCH40 carbon steel pipe and encountered significant flaring after grooving—enough to cause concern about coupling fit and seal integrity. The equipment used was a conventional grooving machine, a model commonly found on the market.

They asked us two straightforward questions:

· What caused this level of flaring?

· Could a Gruvmaster machine have prevented it?

Flaring like this usually stems from two sources: inconsistent pipe support during grooving, and—more critically—a groover that lacks the rigidity to handle high-load applications on thick-walled pipe. SCH40 material demands equipment that won’t flex or vibrate under pressure.

At Gruvmaster, we’ve engineered our systems to manage exactly these scenarios. With a reinforced drive axle, optimized groove profile, and exceptional stability, our machines are designed to control flare—even on large-diameter, heavy-wall pipe—and produce consistently compliant grooves.

So, to answer our client’s question: Yes. This is precisely the kind of issue Gruvmaster helps eliminate.

Pipe Flaring: Natural in Grooving, Controlled by Gruvmaster

Professionals recognize flared deformation at the pipe end as a natural outcome of grooving. However, excessive flaring disrupts coupling alignment, causes sealing failures, and demands rework.

Why Flaring Happens:

It’s All About Pipe Support and Design of Grooving roll sets

1. Operation: Check Your Setup

Most flaring issues stem from one simple mistake: improper pipe support. If the pipe isn’t level—especially if the end you’re grooving is slightly higher than the support.

As the groove roller presses down, the unsupported pipe lifts. The metal forms unevenly, causing excessive flaring at the pipe end. It’s an easy fix: always make sure the pipe is fully supported and level. Take that extra minute to check—it saves hours later.

2. Design: The Machine Matters

Not all groovers are built the same. Flaring isn’t just about operation—it’s about engineering. Specifically, the drive axle diameter and the width of the groove that holds the pipe.

▶ Cheap or worn-out groovers often have a thin drive axle and a wide groove. This combination flexes under pressure. The tool vibrates (“chatters”), tears the metal, and pushes material outward. You end up with a ragged, oversized flare. It’s messy and inconsistent.

▶ With Gruvmaster, we use a bigger, stronger drive axle and a perfectly sized groove. This makes the whole system rigid. No flex. No chatter. Just smooth, even rolling that forms a clean groove with a minimal flare—every time.

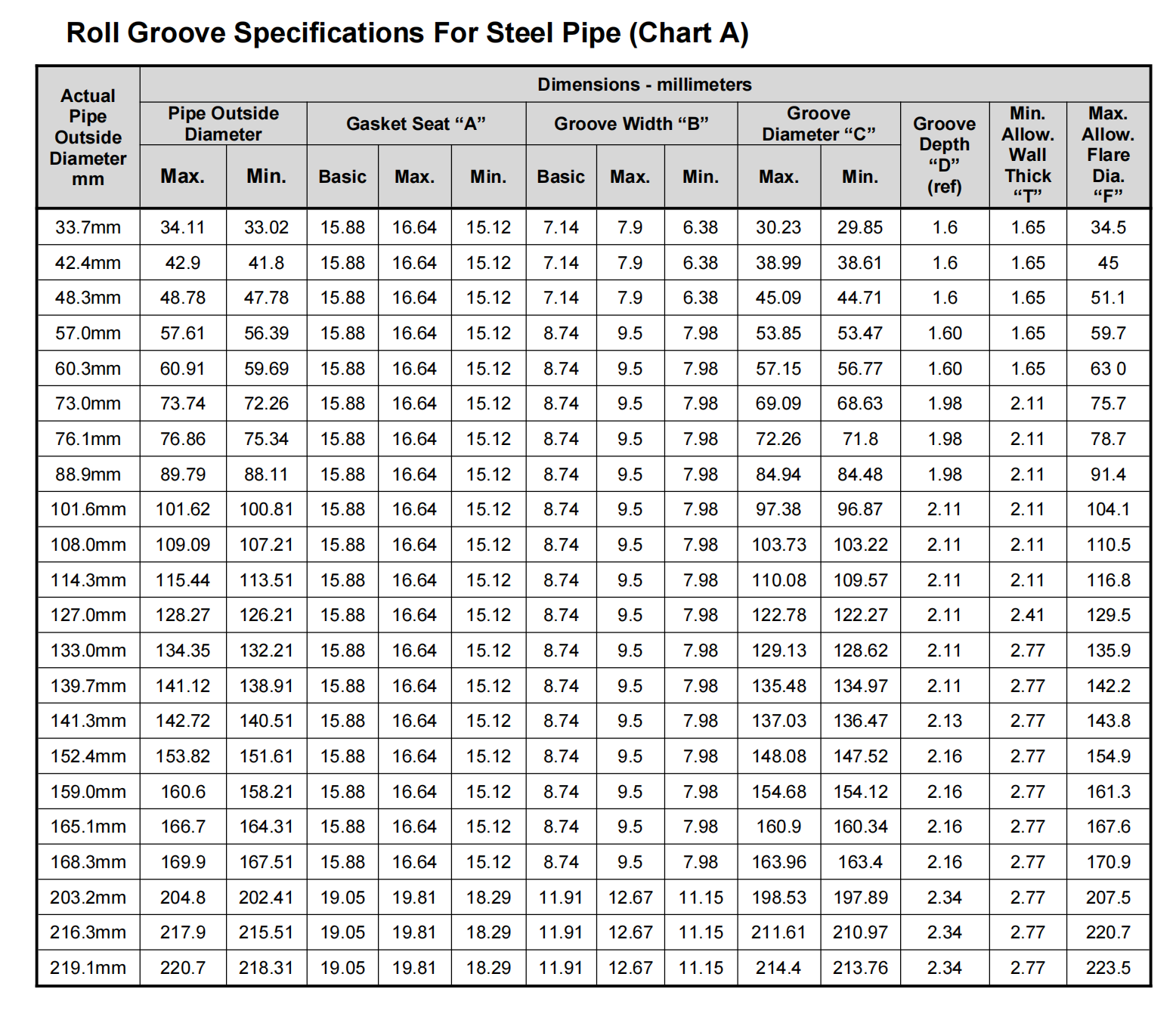

Grooving Machine Models: Data Sheet Below

Burning Flicker: Mildly Compliant, Excessive = High-Cost Risks

When Flaring Becomes a Real Problem,A small, even flare is okay—it’s up to code. But too much flare causes real issues:

✔. Couplings won’t seat correctly → leaks from day one

✔. You waste time hammering and forcing fittings

✔. Risk of rework, failed inspections, and callbacks

It’s not just annoying—it’s expensive !

Gruvmaster's Solution: Achieving Process Precision Through Structural Innovation

Our grooving equipment effectively suppresses flaring through optimized mechanical design and precise machining control, ensuring consistent and reliable groove quality.

▶ Precise Metal Flow Control: The system utilizes a high-rigidity grooving head assembly that guides the metal form path with accuracy, maintaining flare dimensions within permitted standards and delivering groove quality that meets all specification requirements.

▶ Enhanced Operational Efficiency: With significantly reduced vibration and stable operation, the equipment improves first-pass yield while minimizing time losses from rework and additional adjustments, effectively boosting overall roll grooving productivity.

Choose Gruvmaster—where engineering meets efficiency. Get off the jobsite faster with grooves you can trust.