plate edge beveling machine clamp thickness 6-80mm 6400W

- group name

- Pipe cutting beveling machine

- Min Order

- 1 piece

- brand name

- Fusion Equipment and Plumbing Tool|WELPING

- model

- WP-80

- Nearest port for product export

- Shanghai, Ningbo

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA, DDU, Express Delivery

- Acceptable payment methods

- T/T, L/C, MoneyGram, Credit Card, PayPal, Westem Union

- update time

- Mon, 09 Feb 2026 05:56:54 GMT

Paramtents

Color Silver

Volate AC380V/50hz

Application material Stainless steel,alloy steel,carbon steel,Composite

Clamp thickness 6-80mm

Spindle Speed 750-1440r/min (adjustable)

Bevel Angle 0-90° (adjustable)

Power 6400w

Packging & Delivery

- 124cm x80cm x70cm

-

Min Order1 piece

Briefing

The milling machine equiped with commonly used CNC blades to make the customers use the costs more cheaply.

Detailed

INTRODUCTION

DETAILS

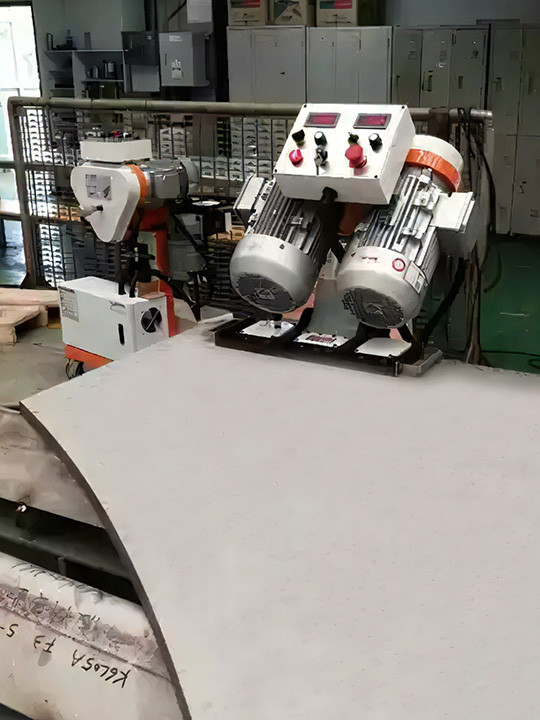

WP-60L Pipe plate Milling Machines can adjust from 0° to 90°

Rear-mounted speed reducer is good for processing narrow plate, and it is

safer Special separate design of Control Box and electrical carbinet make the operation safer Adopt multiply-cutting blades head to process plate beveled edge, therefore the milling speed of each blade is faster and easier.

The surface roughness of plate beveling face can reach to Ra3.2~6.3, it can complete meet the welding demand of pressure vessel Small in Size, light in weight Cold milling method does not affect the material property, no oxidation in beveled surface.

FEATURES

●WP-60L edge milling machine convenient and simple operation.

●The finish of groove is as high as Ra3.2-6.3.

●The milling machine equiped with commonly used CNC blades to

●make the customers use the costs more cheaply.

STANDARD ACCESSORIES |

|

|

Machine body

|

1 Set

|

Blade | 1 pc |

|

Tool box with wrenches

|

1 Set

|

PARAMETER

|

Power

|

AC 380V/50hz

|

Clamp thickness

|

6-80mm |

|

Total

|

6400W

|

Clamp width

|

>100mm |

|

Spindle Speed

|

750-1440r/min

|

Clamp Length

|

>300mm |

|

Feed Speed

|

0-1500r/min (adjustable) |

Work Height

|

820-860mm |

|

Bevel Wdith

|

1-70mm

|

Processing materials |

Carbon Steel |

Single Bevel Width | 1-20mm | Stainless Steel | |

Bevel Angle | 0-60° | Aluminum alloy | |

Automatic clamping (optional) | Composite Plate | ||

PRODUCT DETAILS MAP

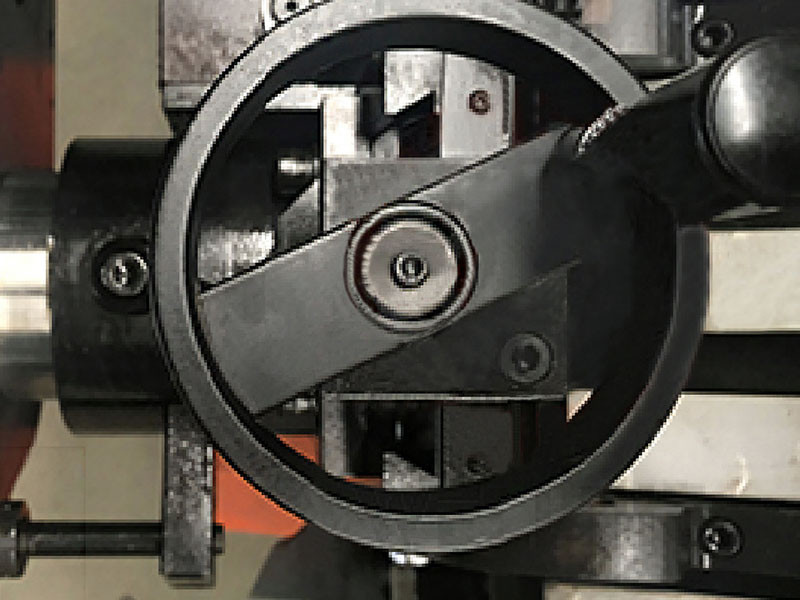

Handle Wheel

Adjust Feed Volume

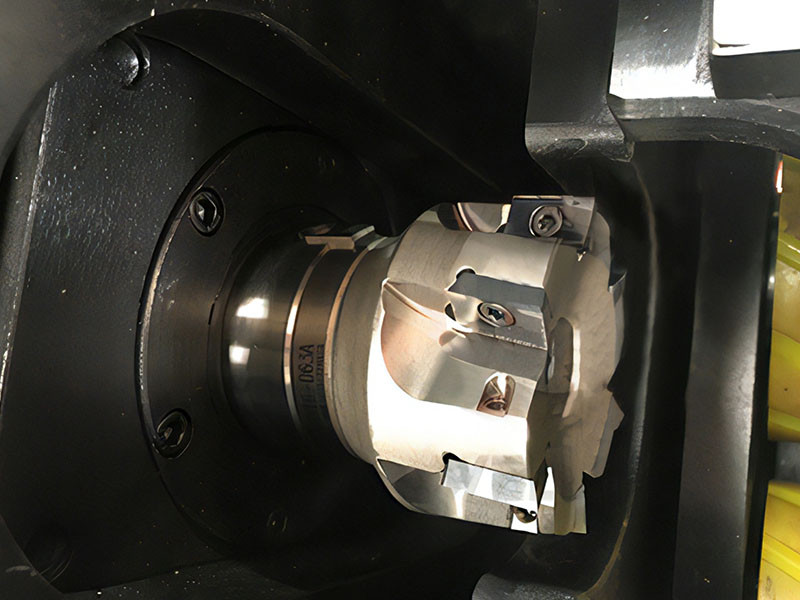

CNC Cutter

High Precision

New Type Cutter

More accurate when processing 90°

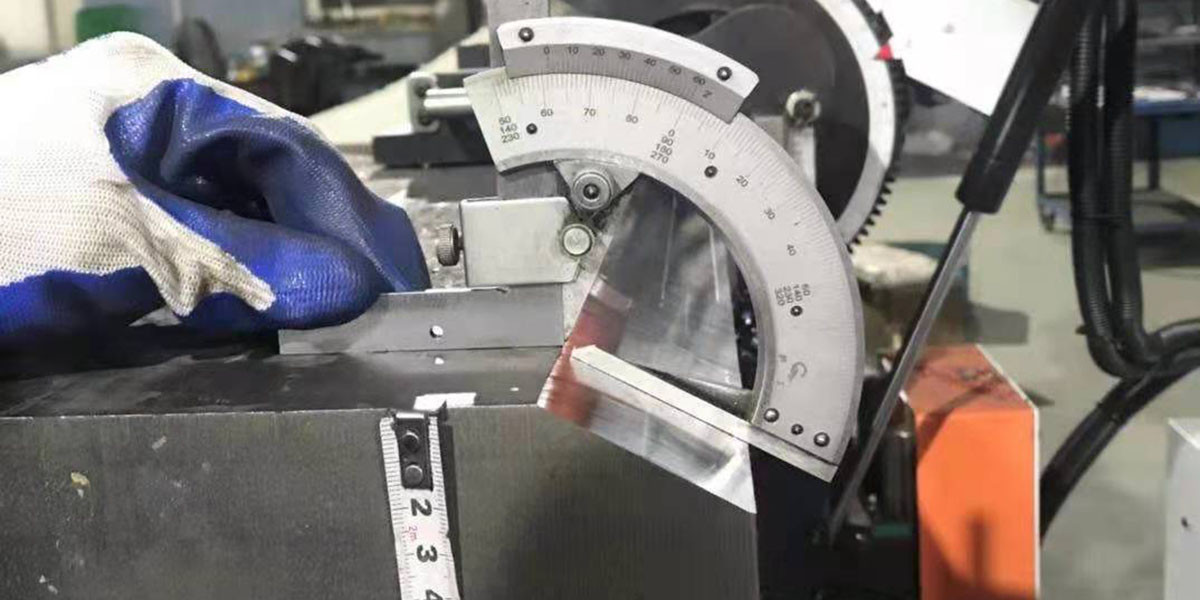

Angle Scale

Adjust Bevel Angle

Rubber Wheel Clamp

More tighter

Protect plate surface not damage

CNC Displayer

Accurate Adjust Feed Speed

Equip with Manual clamp

Auto clamp function is optional

WHAT WE CAN DO FOR YOU?

OUR SERVICES

WELPING develops, manufactures, and sells devices and systems for welding thermoplastics and, in this area, focuses consciously on pipeline systems as the main field of application. And We have been in this field for more than 17 years since 2005.

We aim to bring industrial level design, performance and quality together, to provide professional solutions for a variety of mining & industrial, marine, municipal, irrigation, energy and landfill to help you build reputation.

WELPING is committed to becoming a business for all thermoplastic pipe, which includes the fusion equipment and certified technical training to assist with the installation and fabrication of any plastic pipes related project. WELPING has continually broadened the scope of supply and usage for polyethylene pipe, valve, and fitting system design into new market segments. Also, We help our customers source pipe tools to support their projects. Our success is in the quality of our products and the knowledge and service of our people.