Heavy Duty Electric Hydraulic Roll Grooving Machine for Steel Pipe SCH10/SCH40 2"-16"(RG-6X)

- group name

- Electric Hydraulic Roll Groover

- Min Order

- 1 piece

- brand name

- Fusion Equipment and Plumbing Tool|WELPING

- model

- RG-6X

- Nearest port for product export

- Shanghai, Ningbo

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA, DDU, Express Delivery

- Acceptable payment methods

- T/T, L/C, MoneyGram, Credit Card, PayPal, Westem Union

- update time

- Tue, 30 Dec 2025 18:46:38 GMT

Paramtents

Grooving Capacity 2"-16"

Max Wall Thickness 10mm

Power Supply 1100W

Output Speed 23RPM

Packging & Delivery

- 93cm x74cm x80cm

-

Min Order1 piece

Briefing

roll groovers are designed to improve speed and efficiency for fire sprinkler and other industrial installations

Detailed

2"-16" Heavy Duty Electric Hydraulic Roll Groover

Model RG-6X Electric Hydraulic Roll Grooving Machine is designed to roll grooves on steel pipes and Stainless Steel from 2"-16" (DN50~DN400) SCH10 / SCH40.

The compact large-sized groove machine boasts exceptional versatility and robust performance. Its wide working size range and heavy-duty adjustable bracket make it suitable for pipes of

varying sizes.

Special designed roller set prevents flare on the pipe ends, eases the installation of the grooved couplings.

Inbuilt high-performace gear reducing motor contributes compact size and low noise.

The unique split-type hydraulic system prevents oil leak and extends service life. Groove depth lock nut ensure high quality grooves and high efficiency.

PARAMETER

|

Mode

|

RG-6X

|

|

Suitable materials

|

Carbon Steel,Stainless Steel

|

Grooving Capacity |

for 2"-16" steel pipe SCH10/SCH40

|

|

Power supply

|

220V/110V

|

Frequency | 50HZ /60HZ |

Max wall thickness | 10mm |

Motor power | 1100W |

Output speed | 23RPM |

Packing gross weight | 170kgs |

Packing size | 92*48*87cm |

ORDERING INFORMATION

|

Catalog Number

|

Phase

|

Power

|

Voltage/Frequency

|

|

900060

|

Single

|

1100W

|

220V,50/60HZ

|

|

900061

|

Single

|

1100W

|

110V,50/60HZ

|

STANDARD PARTS

|

Item Number

|

Description

|

Net weight

|

|

|

911022

|

Drive roller 2"-3" (φ60~φ89)

|

1.30kg

|

|

|

911021

|

Drive roller 3 1/2"-6" (φ101~φ168)

|

1.30kg

|

|

|

911020

|

Drive roller 8"-12" (φ219~φ325)

|

1.40kg

|

|

911143 | Drive roller 14"-16"(φ355~φ426) | 1.60kg | |

912010 | Groove roller 2"- 3" (φ60~φ89) | 0.450kg | |

912009 | Groove roller 3 ½" -6" (φ101-φ168) | 0.45kg | |

912008 | Groove roller 8"-12"(φ219~φ325) | 0.45kg | |

912052 | Groove roller 14"-16"(φ355~φ426) | 0.45kg | |

998103 | Pipe stand for 2"-16" (Φ60~Φ426) | 33.0kg | |

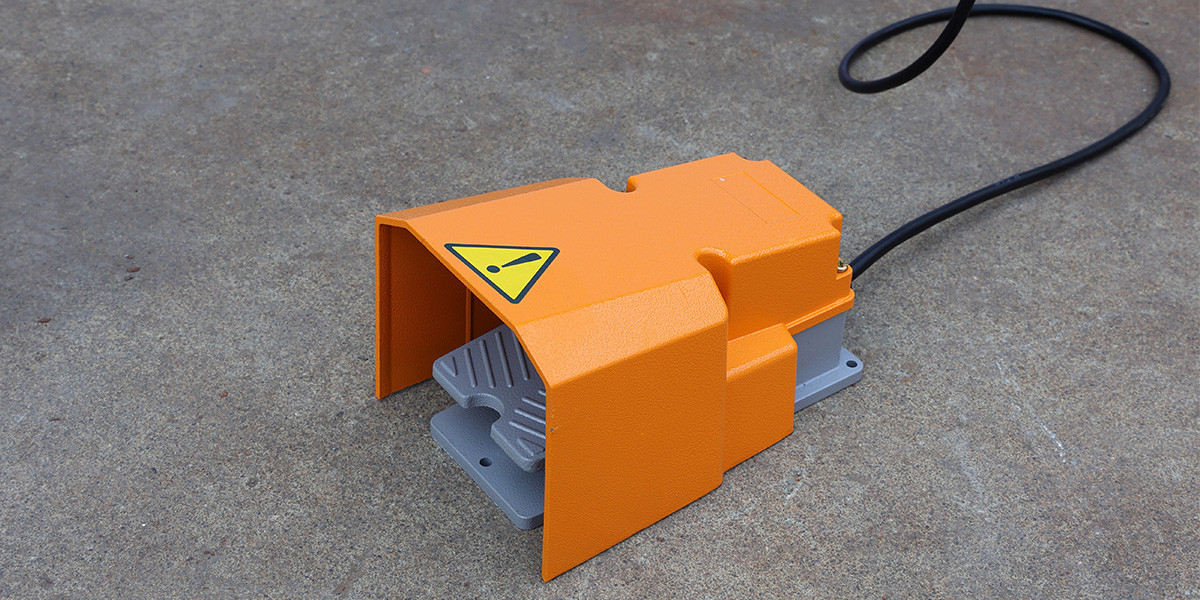

998026 | Foot switch | 1.50kg | |

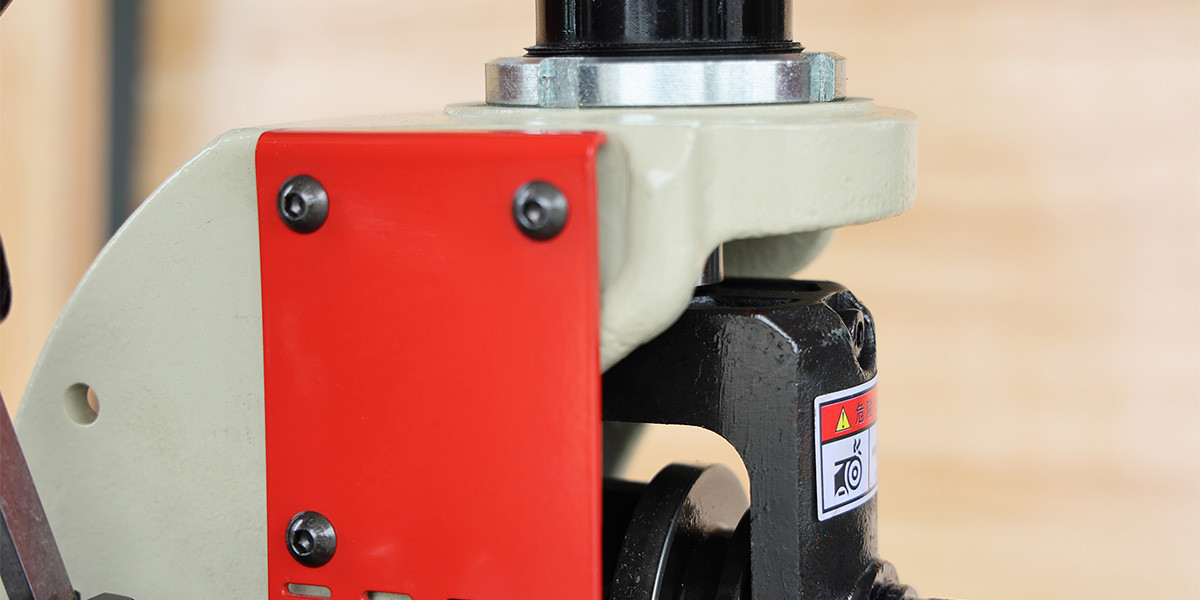

PRODUCT DETAILS MAP

Pipe Stand

for 2"-16" steel pipe

Drive Roller

one set 2"-3" (φ60~φ89)

one set 3 ½"-6" (φ101~φ168)

one set 8"-12"(φ219~φ325)

one set 14"-16"(φ355~φ426)

Groove roller

one set 2"-3" (φ60~φ89)

one set 3 ½"-6" (φ101~φ168)

one set 8"-12"(φ219~φ325)

one set 14"-16"(φ355~φ426)

Foot Switch

DOWNLOAD

WHAT WE CAN DO FOR YOU?

OUR SERVICES

WELPING develops, manufactures, and sells devices and systems for welding thermoplastics and, in this area, focuses consciously on pipeline systems as the main field of application. And We have been in this field for more than 17 years since 2005.

We aim to bring industrial level design, performance and quality together, to provide professional solutions for a variety of mining & industrial, marine, municipal, irrigation, energy and landfill to help you build reputation.

WELPING is committed to becoming a business for all thermoplastic pipe, which includes the fusion equipment and certified technical training to assist with the installation and fabrication of any plastic pipes related project. WELPING has continually broadened the scope of supply and usage for polyethylene pipe, valve, and fitting system design into new market segments. Also, We help our customers source pipe tools to support their projects. Our success is in the quality of our products and the knowledge and service of our people.